Hello, my dear readers? Today I have come up with an article about how to mix food for modern chickens, that is for layers and broiler.

Poultry feed accounts for 80% of production costs. If the breeder is able to make the food himself, he will be able to reduce the costs up to 50 to 60%, this situation will make him profit and return the production costs. The important thing is that the breeder should pay attention to the quality of raw materials during mixing, if you use low quality raw materials you will cause your chickens to stagnate.

My opinion is that if you find it difficult to make the food, then it is better to buy it from companies that focus on the quality of mixing

Poor quality feed causes chickens to stagnate and reduce the level of egg laying, diseases and even death of chickens. For the farmer, making his own chicken feed is one of the ways to focus on the quality of the food as well as reducing production costs.

In addition to the breeder making his own chicken feed, the quality of the raw materials for the preparation should be taken into consideration. The raw materials that are often used in the production of these foods include

whole maize,

corn kernels,

cotton husks,

soybeans,

sunflower seeds,

fish meal or seafood, etc.

In addition to the raw materials I described, the breeder should add other nutrients and various minerals to give the chickens a mix of food with complete nutrients.

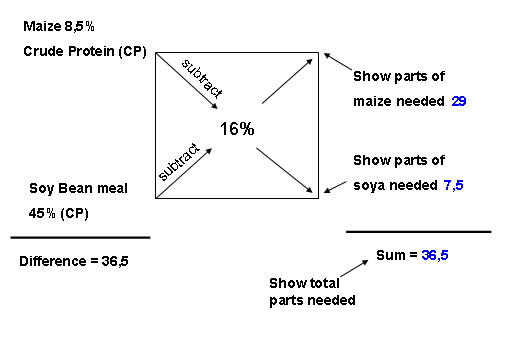

There is a special formula for making chicken feed, the formula is called ‘Pearson Square method’. This formula involves the use of a significant amount of protein in foods called ‘Digestible Crude Protein’ (DCP). This nutrient is very important to understand its level during the production of chicken or other animal foods. The following are the levels of this nutrient ‘DCP’ in various raw materials for making food for chickens or various animals;

Hulled corn = 8.23%

Soy = 45%

Fish meal or seafood = 55%

Corn bran = 7%

Sunflower seeds = 35%

In addition to knowing the levels of DCP, there is another step to find the distribution of nutrients according to the need for the level of protein for the relevant age of the chicken or animal.

Now let’s get rid of those calculations, I have simplified the way to mix these foods in a simple ratio that will be well understood. Proportion is mixing the various raw materials at a level that has already been calculated. Once those levels are mixed, they reach a weight of 100 kg for each complete mix. The following is a breakdown of the mixing weight according to the age of the chickens, these levels have already been calculated, it is just the act of the breeder to buy quality raw materials and mix using these levels.

A: LAYERS CHICKEN

1. Making food for chicks from 1 to 4 weeks (Chick mash) Chicken chicks need a level of important protein (Digestible Crude Protein) ranging from 18 to 20%.

The following analysis works out the weight of 100 kg of food.

Maize 48Kgs

Wheat bran 13 Kgs

A mixture of wheat bran and wheat flour (Pollard) 10Kgs

Sunflower 24 Kgs

Fish/seafood flour 2 Kgs

Lime 2.5Kgs

Flavors (Additives)

Salt 40 Grams (0.04 Kgs)

Premix 30 Grams (0.03 Kgs)

Tryptophan 100 Grams (0.1 Kgs)

Lysine 4 Grams (0.004 Kg)

Methionine 14 Grams (0.014 Kg)

Threonine 90 Grams (0.09 Kg)

Enzymes 70 Grams (0.07 Kgs)

Coccidiostat 82 Grams (0.082 Kgs)

Toxin binder 70 Grams (0.07 Kgs)

Total 100.00 Kgs

2. Making food for 4- to 18-week-old chickens (Growers mash)

These growing chickens need a level of important protein (Digestible Crude Protein) ranging from 16 to 18%.

This combination of food causes the chickens to grow very quickly, in preparation for the laying age.

Analysis:

Maize 14 Kgs

Corn husks 24 Kgs

A mixture of soft wheat bran and some wheat flour (Pollard) 19 Kgs

Wheat bran 14 Kgs

Cotton bales 8.9 Kgs

Sunflower seeds 7 Kgs

Soya flour 5 kg

Lime 3 Kgs

Bone meal 1Kgs

Fish flour or seafood 4Kgs

Flavors (Additives) Salt 37.2 Grams (0.0372 Kgs)

Coccidiostat 1.4 Grams (0.0014 Kgs)

Premix 50 Grams (0.05 Kgs)

Zinc bacitracitrach 1.4 Grams (0.0014 Kgs)

Mycotoxin binder 10 Grams (0.01 Kgs)

Total 100.00 Kgs